How to Insulate a Finished Garage in 2024? 2 Amazing Options Explained!

garagemadesimple.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com . The website is also an affiliate of a few other brands.

How to Insulate a Finished Garage?

Did you just buy this beautiful house of your dreams at a bargain price? It meets all the requirements of your family, even though it was built more than half a century ago. There is only one problem. The garage gets very cold in the winter. So how to insulate a finished garage?

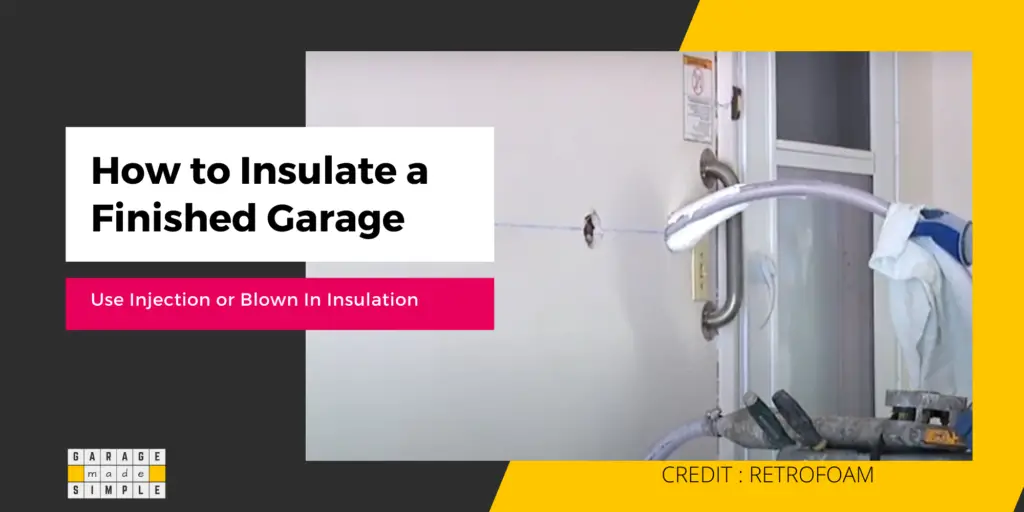

You can insulate a finished garage wall without removing the drywall. There are 2 amazing ways to do it. 1, Injection Foam Insulation 2. Blown In Insulation.

The reason you need to insulate finished garage is to make it comfortable even in the winters. Moreover, you realize that you are losing heat from the house through the uninsulated garage. Your energy bill shoots up in winter. If you insulate finished garage walls, will save you a ton of money.

The walls of the garage have been finished and the drywall is in pretty good condition. So you do not want to tear down the drywall just to put in more insulation.

You can insulate finished garage walls, without removing the drywall by drilling small holes in the drywall and filling in the gap either using Injection Foam Insulation or Blown In Insulation. Each method has its pros & cons, but both are effective and will reduce your energy cost.

In this post I will explain the benefits of insulating garage walls and what is the relevance of R-Value in the world of insulation. I will compare Injection Foam and Blown In Insulation, the pros & cons and how to do it.

So you will be able to make an informed decision as to which process is best for your garage.

Why Insulate Finished Garage Walls? Is It Worth It?

A lot of folks think that insulating a garage just means insulating the garage door. It is understandable. A garage door is large (often 30% of the house frontage) and exposed to the elements.

However, the garage door is only one side of the garage. The walls are the other three sides. And then there is the floor and the roof.

If you just insulate the garage door but not insulate finished garage walls, you are essentially leaving a big hole in your garage insulation plan.

Insulating garage walls benefit you by

- Reducing Energy Costs

- Making the Garage more Comfortable

- Prolonging the life of your Cars

- Preventing Damage to Stored Items

- Reducing Humidity & Condensation

- Keeping adjoining rooms Warmer

- Soundproofing the House

- Preventing Ice forming on Garage Floor

- Ensuring water pipes do not freeze

- Improving Safety

- Adding to Value of the House

Insulating garage walls makes a lot of sense if you live in regions where winters are freezing and brutal. But it also makes a lot of sense if your region experiences temperatures touching or even exceeding 100 deg F in summer.

Want to know more? Read my blog post Insulating Garage Walls Is Better, But You Need To Know Why?

What is R-Value?

Whenever you talk about insulation, be it your house or your garage, you have to talk about R-Value. But what is R-Value? What is its relevance in insulation projects? What R-Value do you need to achieve?

The flow of heat is similar to the flow of water. Water flows downhill. From the mountain top to the sea. That is from a higher level to a lower level.

Similarly, heat flows from a higher temperature level to a lower temperature level. From the warmth of your garage to the freezing cold outdoors.

How do you stop the water from flowing downhill? You build a dam.

How do you stop the garage heat from escaping to the cold outdoors? You use insulation.

Some materials, like fiberglass wool are much better insulators than say steel or a concrete slab. In other words some materials have a higher “resistance to heat flow” than others.

That’s all there is to R-Value for garage insulation (or for that matter any insulation). R-Value is a measure of the “resistance to heat flow”. The higher the R-Value, greater is the “resistance to heat flow”.

Want to know even more? Read my blog post What You Need To Know About R-Value For Garage Insulation.

A material, a door, a wall with higher R-Value is simply better insulation. For walls the recommended R-Value for insulation is R13 – R15 for 2X4 walls and R19 – R21 for 2X6 walls.

This PDF from National Association of Home Builders (NAHB) is also a very useful resource.

What is the Difference between Injection Foam and Spray Foam?

Injection Foam Insulation & Spray Foam Insulation are quite often confused as being the same thing. Well they are not. Both are Foams and both Insulate, but that is where the similarity ends.

Let us take a quick look at Spray Foam Insulation first as that is more commonly used.

Spray Foam Insulation

Spray Foam is actually Spray Polyurethane Foam (SPF). SPF insulation comes in two parts – an iso and a resin in two separate tanks. The two liquids are sprayed together through a spray gun. The two liquids react with each other to form a foam which can be 40X to 100X of original volume.

SPF is very effective as it insulates and air seals wherever it is applied.

SPF comes in two versions:

Open Cell SPF

- Low Density & Soft Material

- Suitable for indoor wall cavities

- Good Air Seal

- Better moisture permeability (allows b-directional drying)

- Low R-Value (3.5 – 3.6 per inch)

- Low cost of insulation

- High soundproofing

Closed Cell SPF

- Medium Density & Rigid Material

- Suitable for exterior applications

- Good Air Seal

- Low moisture permeability (recognized as a flood barrier)

- High R-Value (4.9 – 7.1 per inch)

- Higher cost of insulation

- Low soundproofing

- Increases tensile & bond strength

SPF has to be sprayed on an open cavity, very much like paint is.

Injection Foam Insulation

Injection Foam Insulation is injected into a closed cavity (the space between two studs and the drywall for example) and so can be used to insulate finished garage walls.

Injection Foam hardly expands while Spray Foam expands a lot (40X to 100X) and in a matter of seconds.

On a 2X4 wall you can get an R-Value of 14-16, which meets the requirement.

Both Injection Foam & SPF have good air sealing qualities.

Injection Foam is Open Cell and has some of the properties of Open Cell Spray Foam. It has Lower Density and better moisture permeability than Closed Cell SPF.

Injection Foam is a less messy application than SPF. An exterior application is always preferable but interior application is not very difficult either.

RETROFOAM of MICHIGAN have a lot of expertise & experience in Foam Insulation and you may contact them at https://www.retrofoamofmichigan.com/contact for your specific questions or needs.

How to Insulate Finished Garage Walls using Injection Foam?

First of all you have to make sure that you locate all the closed cavities. Normally the studs of a 2X4 drywall will be 16” apart and the studs of a 2X6 drywall will be 24” apart. But in an old house do not assume that.

You can locate the studs using a stud finder. It is better to check the wall both horizontally and vertically. Sometimes, vertical studs are joined together by horizontal bridging or fire-stops, to increase structural strength.

Stud Finder Wall Scanner

ADVANTAGES:

- Great accuracy/reliability/consistency;

- Identifies the width of stud as well as its location;

- Easy to read screen and the quick identifiers when you hit a stud;

- Increases the sensitivity to more than 2 inches;

- Upgraded model with 5 scanning modes to meet all your different needs.

In case of a single cavity between two studs (the stud bay), you need to drill three holes, through which the Injection Foam hose can be pushed into the cavity. Bottom. Middle & Top.

Remember three holes for each stud bay.

The Injection Foam is pumped first through the bottom hole, then the middle hole and finally the top hole. The holes can then be plugged.

What is Blown In Insulation?

The material that is used in Blown In Insulation is basically the same as that used in making Insulation Batts or Rolls. The difference is that they are in loose fill form. These are:

Cellulose

This is an eco-friendly product as it is made from recycled paper products such as newspaper, cardboard boxes etc. Loose-fill Cellulose has a R-Value of 3.2 – 3.8 per inch, so if you use it in a 2X4 wall, you will be able to achieve an R-Value of 13 – 15 as per the requirement.

All Borate Greenfiber cellulose insulation, available at Home Depot, fills gaps and voids to create an energy saving thermal blanket that can lower heating and cooling costs by 25% and reduce sound power by 60%.

Fire resistant treated insulation is made with 85% recycled material that meets a Class 1 Fire Rating to protect your home and give you more time to evacuate.

Fiberglass Wool

Loose-fill Fiberglass wool is made from glass fibers. Loose-fill Fiberglass wool has a R-Value of 2.2 – 2.7 per inch, so if you use it in a 2X4 wall (most common), you will be able to achieve an R-Value of 9 – 11. That would not meet the requirement.

It works well attics though, because you can build up as much thickness as required. No wonder it is generally used in attics.

Mineral Wool

This is made from blast iron slag and is also referred to as “rockwool”. It has a R-Value of 3.3 per inch and is quite expensive too!

Even then it is a favored Blown In Insulation for Garage walls, especially the ones attached to the home living space. The reason is, it has a very high fire rating.

How to Insulate Finished Garage Walls using Blown In Insulation?

It is a lot simpler to insulate Finished Garage Walls using Blown In Insulation than using Injection Foam. It is even possible to do it yourself.

The home center such as Home Depot will loan you the blower. Buy 20 bags of All Borate Greenfiber cellulose insulation, available at Home Depot and they will give you the blower for 24 hours free of charge.

Unlike, Injection Foam. you need to just drill one hole at the top for each stud bay. You then blow in the insulation using the blower and a long hose. The process is pretty much mess free and safe.

However, Blown In Insulation has one important drawback when compared to Injection Foam. Blown In Insulation does not act as an air barrier, while Injection Foam has excellent air barrier properties.

Bottom Line

The bottom line is that you can insulate finished garage walls, without removing the drywall by drilling small holes in the drywall and filling in the gap either using Injection Foam Insulation or Blown In Insulation.

Each method has its pros & cons, but both are effective and will reduce your energy cost.

When you need to insulate finished garage walls, Injection Foam Insulation is better as you can achieve the required R-Value, high air barrier and high moisture permeability. The downside is that it is messy and requires specialized equipment and expertise. You have to hire a professional which will push the cost up.

On the other hand you can get the required R-Value, when you insulate finished garage walls with Blown In Insulation (both with cellulose & mineral wool). However, it does not provide an air barrier. On the positive side it works out cheaper as you could do it yourself, fairly easily.

Thank you very much for reading the post. I do hope you found it informative and useful.