Vertical or Horizontal Sheathing For Garage Walls: Which is Best?

garagemadesimple.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com . The website is also an affiliate of a few other brands.

Key Takeaways: Vertical or Horizontal Sheathing For Garage Walls

- Both vertical and horizontal sheathing are acceptable for garage walls.

- Horizontal orientation is stronger, easier to install, and cheaper to repair.

- Consider factors like board count, stud spacing, and potential damage when choosing orientation.

- IRC does not specify orientation, but horizontal panels resist higher wind loads.

- Staggering sheathing enhances wall strength and stability.

- Horizontal orientation supports panels on more studs, increasing wall strength.

- Horizontal sheathing allows easier replacement of damaged panels.

Should Plywood Walls in Garage Be Vertical or Horizontal?

So you or your contractor has finished framing your detached garage and you are ready to finish it. There are a range of options available, both for interior walls and exterior siding. Plywood is a good choice, especially for detached garage interiors. So, Should Plywood Walls in Garage Be Vertical or Horizontal?

Both, Vertical or Horizontal Sheathing For Garage Walls, are accepted practices. However, a Horizontal orientation is stronger, easier to install and cheaper to repair.

A standard 2 car garage is typically 20’X20’X8’. But this is not a rule laid down in stone. Your garage dimensions may be different. The actual dimensions of your garage can influence the decision to go vertical or horizontal, when it comes to sheathing the garage walls.

Keep in mind that plywood (and most sheathing materials such as OSB and Drywall) come in boards that are 4’X8’.

You would like to consider the following factors before deciding on whether to go vertical or horizontal.

- The estimated number of boards required to finish the job. For a given wall area, vertical or horizontal orientation could lead to a different result as a result of cutting & wastage.

- Garage wall stud spacing. Typically 2X4 studs are used and these are placed 16” apart on center (OC).

- Likely damage to the bottom end of the sheathing due to a wet floor or impact from moving objects.

- Structural strength requirement. Is your garage going to be subjected to wind or seismic loads?

IRC Code for Wall Covering

Chapter 7 of The 2021 International Residential Code (IRC) covers all aspects of wall covering in home construction. Chapter 7 establishes the various types of materials, materials standards, and methods of application permitted as interior and exterior wall coverings. Some notable points are:

Table 702.3.5, applicable to interiors, allows for gypsum board (drywall) to be oriented in either direction to the framing direction of walls. In essence both vertical and horizontal orientation is acceptable.

When it comes to exterior walls IRC is primarily concerned with the ability of the wall covering to

- form a weather-resistant exterior wall envelope (R703.1)

- prevent accumulation of water within the wall assembly (R703.1.1)

- be capable of resisting wind loads (R703.1.2)

Even for exterior wall covering, IRC does not specify vertical or horizontal orientation. However, horizontally installed panels can withstand higher wind loads than vertically installed panels.

Get the 2021 International Residential Code Spiral-bound Book (International Code Council Series) from Amazon

Can Plywood Be Installed Vertically?

Plywood can be installed in a garage vertically. For some vertical orientation is a preferred orientation for sheathing a wall with plywood, OSB or drywall. This orientation does have some advantages, especially in the case of garages.

Typically garage interiors tend to be 8’ high. Each wall is likely to be 20’ or 24’ wide. The wall frame is made up of vertical 2X4 wood studs that are usually 16” apart on center.

Since sheathing panels such as plywood, OSB and drywall come in 4’X8’, you do not need to do any cutting for installing the panels. Five plywood panels in case of a 20’ wide wall or six panels in case of a 24’ wall can be nailed to the wall frame, straight away.

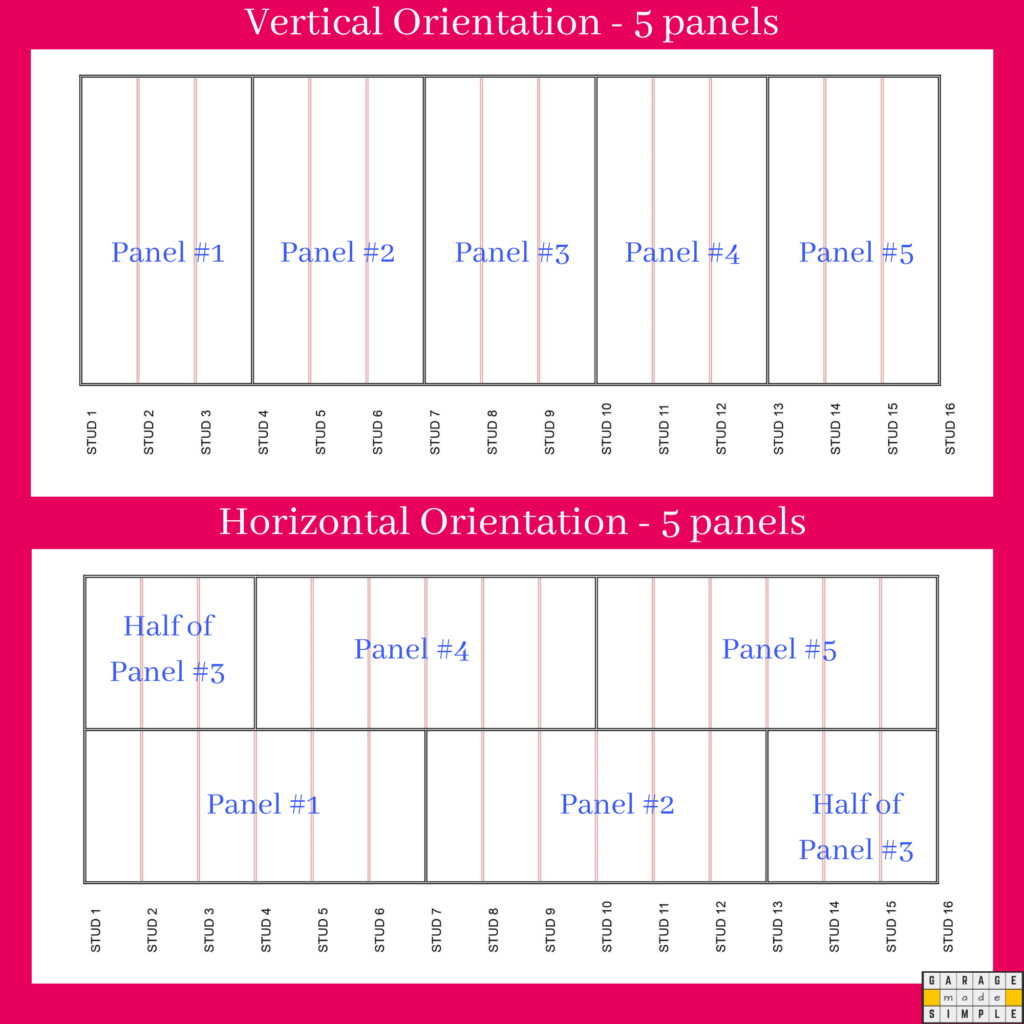

Please see the infographic below for a 20’X8’ garage wall frame.

Installing plywood vertically will save you a lot of effort and time. However, by using a vertical orientation, you are not staggering the panels. This is the tradeoff that you will end up making.

Should Sheathing Be Staggered?

It is always better to stagger sheathing than to not stagger it. You may need to make a few additional cuts to get the stagger effect. But the effort is well worth it as the garage wall will be more rigid. Garage wall finished with staggered sheathing will withstand wind and seismic loads a lot better.

It is generally easier to get a staggered effect with a horizontal orientation, as can be seen from the infographic above.

The staggering is achieved by installing the panels horizontally across the garage wall studs. The next row is staggered by 1/2 panel length (that is 4 feet). The vertical joints will therefore be 4’ apart in each row.

This is ideal for garages as there will only be two rows of plywood (or other sheathing) panels in an 8’ high wall.

Staggering is a technique that has been used, possibly since the stone age, when stones in stone walls were staggered to increase strength.

Is Plywood Stronger Vertical or Horizontal?

Plywood is made from thin veneers of wood peelings from logs. The veneer in each layer runs at right angles to the layer above or below it, giving plywood its strength.

The strength axis of a plywood panel is the direction parallel to the grain of the wood fiber in the face and back surfaces of the panel. Unless specified this is in the direction of panel length.

By installing plywood panels horizontally on a garage wall frame, you increase the strength of the wall by

- supporting the plywood panel on 7 garage wall studs instead of 4 studs in the case of a vertical orientation (refer to the infographic above).

- directing impacts along the strength axis of the plywood

So, all things being the same, a horizontal orientation results in a stronger plywood garage wall as compared to vertical orientation.

DEWALT 20V MAX 7-1/4-Inch Cordless Circular Saw with Brake

DEWALT 20V MAX 7-1/4-Inch Cordless Circular Saw with Brake

This DEWALT 20V cordless circular saw gives you with the power and depth-of-cut of a corded circular saw, but with the portability and convenience of cordless.

DEWALT brushless motor technology delivers excellent performance and runtime when cross cutting 2x material and ripping sheet goods.

Horizontal Sheathing is Easier to Replace

Most of the damage caused to a garage wall, irrespective of the type of sheathing, is to the bottom portion. The lower part of the garage wall is at the risk of

- picking up moisture from the a wet or damp garage floor. The garage floor can easily get wet due to condensation, seepage, leaks, water pooling from rain, snowmelt and carwash. Plywood is relatively moisture resistant but OSB can swell up and deform, while drywall can all but crumble away.

- mold growth due to the moisture pickup

- attacks by pests especially termites

- impacts from cars, gardening equipment, furniture movement, etc.

You would, of course, take all possible steps to protect the bottom of drywall, OSB or plywood sheathing on the garage wall. But damage can still happen. At times, the damage may be so bad that you may have to just replace the panel.

In this situation you will be happy that you used a horizontal orientation. You will get away by replacing just the bottom half of the garage wall sheathing. In case, you have chosen to go with a vertical orientation, you will need to replace all the panels.

Metabo HPT Framing Nailer

Metabo HPT Framing Nailer (NR90AES1)

The NR90AES1 framing nailer drives plastic collated nails from 2″ up to 3-1/2″ in length and features Metabo HPT’s next generation “industrial design.”

The NR90AES1 framing nailer is great for flooring and framing, truss build-up, window build-up, sub flooring, roof decking, wall sheathing and housing construction.

Bottom Line

The bottom line is that both vertical and horizontal orientation are accepted practices for sheathing a wall in general. However, in the case of plywood sheathing of a garage wall, I recommend going for a horizontal orientation.

You will benefit because horizontal orientation

- allows easy staggering

- is stronger as the panel is supported by more studs

- directs impacts along the strength axis of the plywood

- lets you replace just the bottom panels in case of damage

Thank you very much for reading the post. I do hope you found it informative and useful.