Concrete Garage Apron: Basics, Best Practices & Installation Guide

garagemadesimple.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com . The website is also an affiliate of a few other brands.

What is a Concrete Garage Apron?

The concrete garage apron is the concrete slab in front of the garage door and is used to transition the concrete or asphalt driveway onto the garage concrete floor. This is necessary as the two surfaces are on two different grades.

The apron is between 2 to 6 feet wide and runs the entire width of the driveway and the garage door. At times it may run around the entire perimeter of the garage.

The concrete apron is used to

- Provide a visual demarcation between the garage and the driveway. This is why often it will have a different color. Sometimes the concrete garage apron may even have a stamping on it.

- Provide a gradual slope between the two different levels of the concrete garage floor and the driveway.

- Keep the two surfaces apart as they have different subgrades and experience different freeze thaw cycles and other stresses.

- Divert rainwater and snowmelt from entering the garage or seeping into the garage foundation.

- Install radiant heating to melt snow in a jiffy.

So the concrete garage apron has some very important functions beyond just aesthetic appeal.

If you live in Florida you should contact Aurora Asphalt & Concrete for your Concrete Garage Apron needs. They have the expertise and experience to take on any asphalt or concrete job.

This is an excellent example of their workmanship!

Why do You Need a Concrete Garage Apron?

The concrete garage apron is necessary to provide a transition between the driveway level and the garage floor. The driveway is not always level with the garage floor.

The Concrete Garage Apron helps in the Transition

Even if the driveway started off being level, it will ultimately sink below the garage floor. The garage floor is on a foundation & footings and is less likely to sink.

The driveway on the other hand is “slab on grade” and is more likely to sink as the subgrade may be eroded by rainwater.

The concrete garage apron acts as a transition between the two different levels. Concrete garage aprons are poured in a gradual slope from the driveway to the garage floor.

This ensures you are not scraping the bumpers of your car as you pull in or out of the garage.

The Concrete Garage Apron can be used for Water Diversion

When your driveway slopes towards the garage, as is sometimes the case, it is necessary to install a drain, parallel to the garage door onto the concrete garage apron.

Without such an arrangement rainwater or water from the melting snow on the driveway, will come rushing in and flood the garage. The drain will trap the water before it happens and safely divert it to the storm water drainage system.

A Garage Water Diverter is basically a trench drain that is installed in the concrete garage apron or at the junction of the driveway and the apron. Traditionally these drains are wide and covered by steel grates.

The steel grate covers help collect the water while preventing debris from flowing into and clogging the drain.

A trench drain in the concrete garage apron is very helpful in making your garage flood proof.

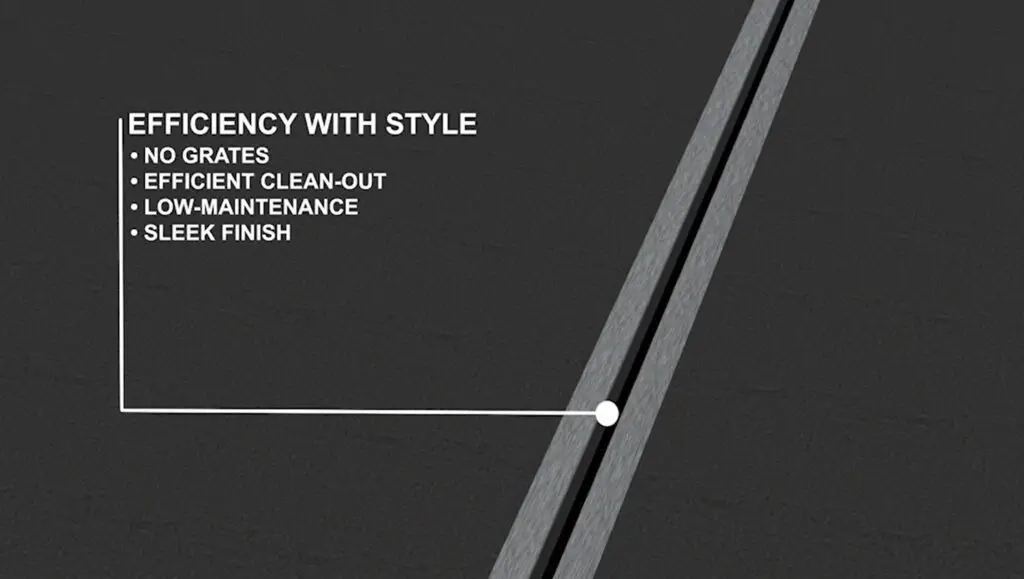

U Drain is a Modern Style Trench Drain

When it comes to the use of a water diverter, I really like the modern look of trench drain from U-drain a company from Canada. The SINGLE SLOT INTAKE has revolutionized the trench drain industry. It has a sleek look and is far easier to maintain.

The benefits of U-drain are:

Once your concrete apron has been poured, U-drain™ is fully encased. Only the slot is visible. This provides a sleek finish. It is very easy to clean too. Simply insert the cleaning paddle and run it along the length of the drain to the sump pit.

Disclaimer: We are not an affiliate and have no financial or other benefits from U-Drain. Just think they have some great products and you may find what you are looking for at their website.

Radiant Heating Installed in the Concrete Garage Apron will help in Snowmelt

Do you hate shoveling snow piled overnight in front of your garage door? Well, who doesn’t? Here is a really cool idea (warm actually!) to make your life super easy.

Install radiant heating in your concrete garage apron! The snow will melt away at the press of a button.

No more spraying. No more sprinkling salt. And if you have installed a drain in the concrete garage apron, as you must, the snow melt will quietly flow away into the storm water drain.

Radiant heating can use electric coils or hot water pipes. The principle is the same in both cases. The wonderful folks at WarmlyYours have this lovely schematic, which explains it all.

Disclaimer: We are not an affiliate and have no financial or other benefits from WarmlyYours. Just think they have some great products and you may find what you are looking for at their website.

Concrete Garage Apron: Best Practices Guideline

When it comes to the curbside apron, you must comply with the building code in your area. However, there are usually no building codes for the concrete garage apron.

I am listing down the “best practice” guidelines that you or your contractor should follow to get good results.

Length: The length of the apron should be equal to the width of the driveway or the width of the garage, whichever is higher. Though not necessary, you can certainly extend the concrete garage apron in a manner that it becomes the perimeter of the garage.

Width: There are really no rules here. Typically concrete garage aprons are between 2’ to 6’ wide. A wide apron allows you to incorporate a water diverting drain and radiant heating.

Thickness: The concrete in the garage apron should be 4”. Less than this will not give you the required strength and the apron will crumble in no time.

Concrete: Concrete with a strength of 4000 psi is most suitable for the garage apron. Use of fiber reinforced concrete is preferable. Alternatively, use rebar or wire mesh reinforcement.

Using both fiber reinforced concrete and rebar or wire mesh reinforcement. Will only increase the strength & durability of the concrete garage apron.

TIP: Always place rebars or wire mesh on “chairs” so that they are embedded within the concrete slab.

Placing them on the grade or the polystyrene insulating panels does not help at all as it does not get embedded into the concrete slab and is a waste of money.

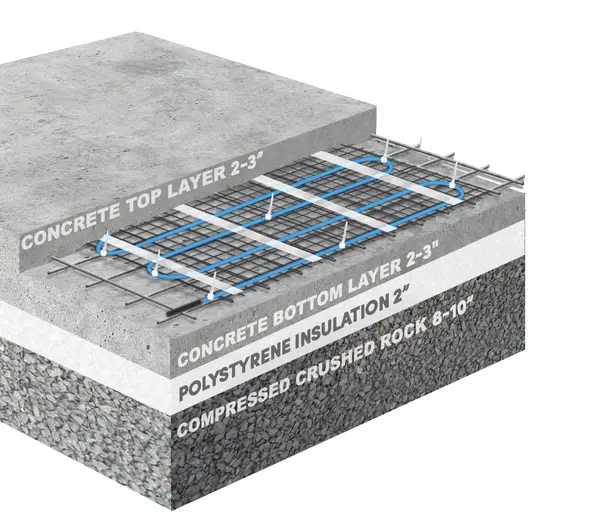

Insulation Panels: Place 2” of Polystyrene Insulation Panels directly onto the tamped grade. This is an absolute must if you are going for radiant heating.

Vapor Barrier: Using a Vapor Barrier directly under the concrete slab gives the best results.

Concrete Garage Apron: Step-by-Step Installation Guide

Preparing the grade and pouring concrete for a garage apron is not much different from pouring a “slab on grade”. Of course there are a few differences. Here is what you need to do.

Step 1: Removing the Old Apron

If you already have a garage apron but you wish to replace it because it has sunk, cracked, crumbled, etc. and is no longer usable. If you do not have an existing garage apron, then your driveway would be coming up to the garage door.

In any case you have to remove the concrete or the asphalt, where the concrete garage apron needs to be installed. Use a pry bar to create voids under the old concrete slab or asphalt and then break it up using a sledge hammer.

Ensure that you remove the existing apron or driveway completely till you reach the grade. Move away the debris in a wheelbarrow.

It is back breaking but can be done. (Try to choose a cool day for this).

Step 2: Digging the Hole for Apron Base

Mark out the apron area by driving stakes at the four corners. Remove the topsoil and dig a rectangular hole. The depth has to account for 4” of concrete, 2” of insulation and 4” to 6” of a rock & gravel base (if it does not exist already).

Step 3: Preparing the Concrete Garage Apron Base

The exposed soil should be smoothed and any low areas filled up. Tamp the surface using a hand or mechanical tamper such that the soil is firm & level.

Next put layers of compactible gravel, crushed stone or recycled concrete for providing the strength to the base. The layers must be compacted at each stage for a strong and solid base.

Lastly add a couple of inches of gravel and compact it. This will help in drainage.

The entire base should be pitched towards where the drain will be or away from the garage door.

Step 4: Placing the Drain & Insulation

With the base ready, it is time to lay out the drain and check that the slope is right. The drain has to end in a sump tank.

Flow of water from the sump tank to the storm water drain can use an electric pump or just good old gravity, if you have the height.

The remaining part of the base is then covered with 2” polystyrene insulation panels.

Step 5: Installing Vapor Barrier & Reinforcement

Now cover the insulation panels with a good quality 10 mil thick vapor barrier. Make sure that it has no holes and edges overlap and are sealed with tape.

If you are not using rebar, you can use either a wire mesh or concrete with fibers. Some people like to use both. More peace of mind and lower risk of cracks at a marginally higher cost.

When using rebar or wire mesh ensure that they are raised above the compacted surface. They should be embedded within the concrete slab. Do this by putting them on “chairs”.

Just laying them on the compacted surface does not help at all. They will not add any strength to the concrete slab.

Lastly, lay out the pipes for the Radiant Heating hot water.

Step 6: Pouring the Concrete

The important things to keep in mind before and during the pour are:

Concrete Quality:

Use the right strength concrete. The concrete should be 4000 psi. If the concrete is of that strength then the water to cement ratio will be less than 0.5.

It will not be runny. While it will be harder to work with, it also means that you can get the required slope.

Always choose concrete with fiber reinforcement. Fibers not only strengthen the concrete but will also prevent the concrete from cracking.

The Slope:

Get the right pitch towards the drain early on. Before the concrete mix begins to set and harden.

For water to flow smoothly towards the drain, the pitch should be 2%, that is 2” for every 100” length. The pitch could go upt 5%, but any higher and there is a risk of scraping the bumpers as you drive over the apron.

Expansion & Contraction Joints:

You always need contraction and expansion joints in concrete slabs.

Install the foam expansion joint to create a gap between the apron and the garage slab. The expansion joint will allow the concrete garage apron to expand on hot days, without pushing against the garage floor.

As the concrete garage apron for a two car garage may be 24’ in length, 3 to 4 contraction joints would be required. Contraction joints can be grooved in during the finishing stage or sawed into the concrete garage apron, a couple of days after the pour.

Step 7: Finishing the Concrete Garage Apron

Once the concrete has been poured you need to wait for the it to reach the desired finishing stage. Depending on the weather conditions and the concrete mix, it is typically around 2-4 hours after the pour.

Now you can float the surface. Use a bull float or a trowel to float the surface in a back-and-forth motion. This helps to remove any ridges or imperfections and create a smooth finish.

Edge the slab to create a clean, finished edge around the perimeter of the slab. Use an edger to tool the edges of the slab to a rounded or beveled profile.

You can groove in the contraction joints in to the slab at this point. This will help to prevent cracking by creating controlled joints in the concrete. Use a grooving tool to cut grooves into the slab, typically about 1/4-1/2″ deep.

Cure the concrete. This is the most important step in finishing concrete. Curing allows the concrete to develop its full strength and durability. Keep the concrete moist for 7-10 days by covering it with plastic sheeting or burlap.

The concrete garage apron will cure to its full strength in 4 weeks. Try not to use it in this period, certainly not for heavy loads.

Bottom Line

The bottom line is that the concrete garage apron is an important link between your garage and your driveway. Specifically it

- Acts as a visual demarcation

- Provides the required slope between two levels

- Separates the two as they experience different freeze thaw cycles

- Can incorporate the drain to divert rainwater & snowmelt

- Can have radiant heating to melt snow easily

Thank you very much for reading the post. I do hope you found it informative and useful.