Running Exposed Romex in Garage: Code & Best Practice

garagemadesimple.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com . The website is also an affiliate of a few other brands.

Is Running Exposed Romex in Garage Permitted?

Romex® NM-B is a nonmetallic-sheathed cable and is primarily used in residential wiring as branch circuits for outlets, switches, and other loads.

Running exposed Romex in garage is not permitted by the NEC code. Romex can only be run in garage provided it is concealed behind 15-minute fire rated sheathing or within a conduit as specified by NEC code.

Romex® is in fact a brand name but the name has become generic and is used as to refer to all NM cables (even of other brands). So the term Romex shall be used to refer to all NM cables (even of other brands), throughout this article.

Why Can’t Romex Be Exposed?

Romex Cable has either two or three individual conductors that are sheathed in a tough PVC thermoplastic. The sheathing is an insulator and is resistant to fire & moisture.

However, the sheathing is still not considered strong enough for exposed, damp & moist conditions. It is susceptible to physical damage which can expose the wires (conductors) inside.

Any physical damage to the sheathing of a Romex Cable can result in short-circuiting, fire, electrical shock and even electrocution.

Both code and common sense therefore require that you should not run Romex in your garage if it is going to be exposed.

What Article in the NEC Covers NM Cable?

Article 334 of the 2020 National Electrical Code (NEC) is specific to Nonmetallic-Sheathed Cable, commonly known as Romex Cable. It covers the use, installation and construction specifications of NM cables.

Article 334.10 Uses Permitted

The following, which forms a part of Article 334.10(3) is worth noting:

Cables shall be concealed within walls, floors or ceilings that provide a thermal barrier of material that has at least a 15-minute finish rating as identified in listings of fire-rated assemblies.

This makes it absolutely clear that Romex Cables shall be concealed within a 15-minute fire-rated sheathing such as drywall.

Article 334.15 Exposed Work

The following, which forms a part of Article 334.15(B) is worth noting:

Protection from Physical Damage: Cable shall be protected from physical damage where necessary by rigid metal conduit, intermediate metal conduit, electrical metallic tubing, Schedule 80 PVC conduit, Type RTRC marked with the suffix -XW, or other approved means.

This makes it very clear that when NM cable is not concealed behind a wall, floor or ceiling it must be within a conduit as specified above for protection from physical damage.

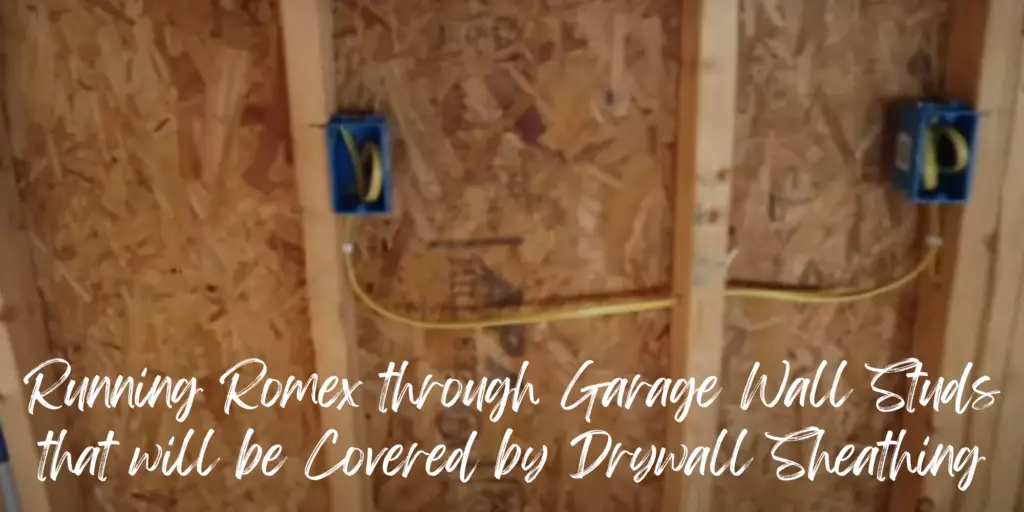

The above Article also implies that Romex Cables can not be run across the front face of studs or ceiling joists or be attached across the face of concrete foundation walls. Running Romex Cables through holes drilled in the center of studs or joists is not only acceptable but considered the best practice.

Article 334.30 Securing and Supporting

The following, which forms a part of Article 334.30 is worth noting:

Nonmetallic-sheathed cables shall be secured and supported by staples, cable ties listed and identified for securement and supports, or straps, hangers or similar fittings designed and installed so as not to damage the cable, at intervals not exceeding 1.4 m (4 ½ feet) and within 300 mm (12 in.) of every cable entry into enclosures such as outlet boxes, junction boxes, cabinets, or fittings.

Further

The cable length between the cable entry and the closest cable support shall not exceed 450 mm (18 in.) Flat cables shall not be stapled at edge.

In other words, Romex Cable installation in a garage should be secured & supported even when it is concealed behind the drywall.

- The distance between fasteners should not be more than 4 ½’

- The distance between fastener and cable entry into a box or fitting should not be more than 12”

- The distance between closest fastener and cable entry should not be more than 18”

Condition of the Fasteners

The code requires that the fasteners are well-maintained. This is to ensure that the fasteners do not rust or become loose and result in Romex Cables sagging.

Consequently the code does not permit the use of Romex Cables in the garage as an extension cord or temporary wiring. Romex Cables that are exposed and not secured and supported are not permitted by the code.

Article 334.12(b)(4) Uses Not Permitted – Type NM

The above article prohibits the use of Romex Cables “in wet or damp locations”.

This implies that Romex Cables can not be used, even when encased in a conduit, in following locations:

- Underground such as in cable from main panel in the house to the subpanel in the garage

- Outdoors such as in cable for garage door lights, driveway lights, landscape lights, etc.

Article 300.5(B) Underground Installations – Wet Locations

Part of the above article defines “wet locations” as:

The interior of enclosures or raceways installed underground shall be considered to be a wet location.

Can Romex Be in Contact with Insulation?

Absolutely! In fact insulation such as fiberglass, mineral wool, etc. actually helps secure Romex Cables and keeps them in their place.

Install the insulation in the stud cavity bays only after you have run the Romex Cables through the studs in the garage wall. Loose fill insulation will easily adjust around the Romex Cables. In case of insulation batts, just cut them into two pieces at the right height. One piece goes below the cable and the other above it.

The Romex Cables used must, of course, be new and the Nonmetallic-sheathing must be intact. Do not use Romex Cables, in any case, if the Nonmetallic-sheathing is damaged. There is a very high risk of short-circuiting, fire, electric shock and even electrocution.

What Is the NEC Code for Conduit Fill?

Chapter 9, Tables, at the end of the 2020 National Electrical Code Book. Table 1 gives the conduit fill %age.

Table 1 Percent of Cross Section of Conduit and Tubing for Conductors and Cables

| Number of Conductors and/or Cables | Cross-Sectional Area (%) |

| 1 | 53 |

| 2 | 31 |

| Over 2 | 40 |

For example, a 12-2 Romex Cable needs to be run through a ¾” conduit to ensure that the conduit fill does not exceed 53%.

However, most electricians will not pull a Romex Cable through a conduit. It is just too much work with few benefits. It is better to pull THHN/THWN wires through conduits. Of course Table 1 of Chapter 9 of the NEC is still applicable.

TIP: Click on Link for Conduit Fill Calculator from Southwire, manufacturer’s of Romex Cables & Other Wires & Cables to easily calculate conduit fill percentage.

Advantages of Using Romex Cable

Romex wire is a popular choice for do-it-yourselfers as it has the following advantages:

- Lighter weight: Romex wire is lighter than metallic sheathed wiring, making it easier to handle and install.

- Easier to unspool and straighten: The PVC sheathing on Romex wire is pliable, making it easier to unspool and straighten without kinking.

- Easier to pull through holes in studs: The smooth sheathing on Romex wire makes it easier to pull through holes in studs without jamming or getting stuck.

- Easier to cut and rip: Romex wire can be cut with a set of side-cutting pliers or wire snippers, and it can be ripped by hand.

- Easier to attach: Romex wire can be attached to framing members with lightweight plastic cable staples.

- Coated in patented SIMpull Cable Jacket for easier pulling, stripping, and installation

- Romex Type NM-B Copper Building Wire is ideal as a branch circuit for switches and outlets

- Installation above ground and in dry locations only

- The voltage rating of the cable is 600 volts

Downside of Romex Cable

The main downside of Romex wire is that it can only be used in certain situations. It cannot be used outdoors, in wet locations, or underground. It also cannot be used for commercial projects.

DISCLAIMER: What Is the Safest Way to Handle Electrical Wires?

This post is for information only. I strongly recommend that all electrical work should be entrusted to licensed professional electricians. In case you do decide to do some of the work yourself, make sure that:

“Treat all electrical wiring, even “de-energized” ones as if it is live, unless it has been locked out and tagged”

You must follow the basic safety guidelines, as under:

- Use protective eyewear, especially when drilling or grinding metal

- Wear insulated rubber gloves when working on any circuit or branch circuit

- Always use insulated tools while working with electricity

- De-energize the electrical wires on which you will be working. Tag the circuit breaker to prevent someone from switching it on accidently

- Electrical wiring in wet or damp locations or underground must be within a PVC conduit

- Underground wiring conduits should be at least 18 inches below grade as per code

- All receptacles for equipment that could be in wet or damp locations should be equipped with Ground Fault Circuit Interrupter (GFCI)

- Never use old frayed cables, damaged insulation or broken plugs

- High voltage equipment should be properly grounded to insure electricity flows directly to the ground and not through the person in contact with the live wire

Thank you very much for reading the post. I do hope you found it informative and useful.