Can You Recoat RockSolid? A Guide to Get Best Results!

As an Amazon Associate, I earn from qualifying purchases.

Can You Recoat RockSolid?

Rust-oleum RockSolid is the best garage floor coating in the market. The manufacturers claim that the coating has a life of twenty years.

In spite of the extremely high durability of the coating, there may be reasons when overcoating or recoating Rust-oleum RockSolid may become necessary. So can you Recoat RockSolid?

Yes you can Overcoat or Recoat RockSolid. As a matter of fact it is highly recommended to apply a clear topcoat to enhance both the looks and the performance characteristics of RockSolid Garage Floor Coating.

Key Takeaways – Recoating Rust-Oleum RockSolid Garage Floor Coating:

- Recoat to enhance appearance and performance.

- A Recoat helps lock in colored flakes, fix mistakes, repair damage, or refresh your garage.

- A Recoat can also help in providing anti-skid properties, UV protection, and a glossy finish.

- Always follow instructions for surface prep, curing, degreasing, moisture control, and optimal application conditions.

- Apply the topcoat 8-12 hours after the initial coating (non-tacky) and within 7 days. Sand if recoating after 7 days.

The reasons for overcoating or recoating Rust-oleum RockSolid include:

- Overcoat with a clear topcoat to either enhance looks or performance, usually both.

- Overcoat with a clear topcoat to lock in the colored flakes

- Overcoat to cover up application mistakes

- Touch up or completely recoat to repair accidental mechanical damages

- Recoat to give a fresh look to the garage

Whatever your reason, you will need to know your recoating options and the best way to do it. In this post, I shall give you all the important facts that you need to know.

Does RockSolid Need a Top Coat?

Rust-oleum RockSolid Polycuramine Coatings combine the best of Polyurea, Urethane and Epoxy chemistries. It is not essential to use a top coat on RockSolid Coating, but a top coat is recommended to enhance both the looks and the performance characteristics of RockSolid Garage Floor Coating.

Correctly chosen, a Topcoat can:

Help Lock In Colored Chips

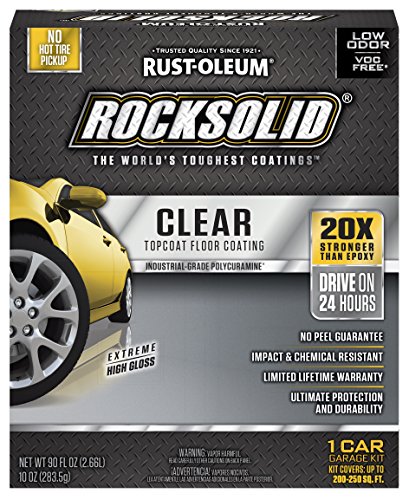

RockSolid is a 100% solid Polycuramine which is self levelling. The most convenient way to apply this product is by using a Garage Floor Coating Kit. The kits come in two sizes:

- 1 Car Kit (90 fl oz) – Covers up to 200-250 sq ft

- 2.5 Car Kit (180 fl oz) – Covers up to 450-500 sq ft

The kits come along with Decorative Color Chips. The chips are broadcast on the “still wet” RockSolid surface. The chips get embedded in the coating surface, but do not sink due to surface tension.

However, not all chips land on the paint surface in a perfectly horizontal position. Many get embedded at an angle and can get dislodged quite easily. Moreover, you end up with a somewhat uneven surface.

By recoating Rust-oleum RockSolid with Rust-Oleum RockSolid Polycuramine High Gloss Clear you can seal and locking in the decorative colored chips.

However, do keep in mind that polycuramine clear topcoat is non-yellowing only in interior applications. It yellows. if applied outdoors.

RockSolid Polycuramine High Gloss Clear Coat

- Extreme high-gloss Clear topcoat provides a protective finish that resists cracking, peeling, chemical spills and hot tire pick up over bare or coated concrete

- Self-leveling, Low odor and Low VOC

- Complete projects quickly; coating is walk on ready in 8-10 hours and vehicle ready within 24 hours

- Kit covers a 2 1/2 car garage over coated concrete and a 1 car garage over bare concrete

Incorporate The Anti-Skid Additive

Rust-oleum RockSolid, like many high gloss and super smooth floor coatings, can be slippery when wet. It is quite common for garage floors to be wet due to condensation, rain water, snowmelt etc.

Overcoating Rust-oleum RockSolid with Rust-oleum RockSolid Gloss TopCoat Floor Coating and incorporating Rust-oleum Anti-Skid Additive in it will make your garage floor less slippery and more safe.

Protect From UV Radiation

Rust-oleum RockSolid does not have good resistance to UV light. The manufacturer Rust-oleum does not recommend use of RockSolid in outdoor applications.

A garage floor may get a fair amount of sunlight if it has windows or the doors are open for long durations. This can lead to loss of color of the RockSolid garage floor coating over a period of time. Since the sunlight may not fall across the entire floor, it may end up with color variation.

Overcoating RockSolid with a Polyaspartic Clear Topcoat, which is UV resistance and will enable your RockSolid garage floor coating to retain its color for years to come.

I recommend using Rust-Oleum 277499 FastKote UV Stable Polyurea Floor Coating. FastKote® UV is a high gloss, UV stable aliphatic polyurea floor coating for use in industrial and commercial facilities. Suitable for both interior and exterior applications.

Enhance The Looks

Rust-oleum RockSolid already looks fantastic on a garage floor, especially with the Decorative Color Chips. But if you want to take your garage floor to yet another level, a clear topcoat can add even more gloss.

Recoating Rust-oleum RockSolid with Rust-Oleum Floor Topcoat Clear Shimmer Gloss will give your garage floor a wet glossy look that will certainly become the talk of the neighborhood.

How To Avoid Application Mishaps

In case the first application of Rust-oleum RockSolid does not turn out to be satisfactory, then recoating Rust-oleum RockSolid will help to improve the garage floor coating and meet your expectations.

Rust-oleum RockSolid is self-leveling and hence relatively easy to apply. This is an important reason it is sold in Garage Floor Kits. You do not have to be a handyman to apply it.

But mishaps can happen and the application can go wrong.

It is more likely that you may have not followed all the instructions exactly. Here are some of the important ones:

- New Concrete floor must have fully cured (requires 4 weeks)

- Degrease the surface to ensure there are no oil stains

- Surface must be free of dust and other contaminants

- The concrete floor should be free of moisture

- Topical Sealer should be removed to ensure RockSolid can adhere to concrete

- Surface must be etched or abraded, if it is sealed or too smooth, for proper adhesion

- Old paint from existing coating must be in sound condition

- Peeling paint must be removed with a wire brush or scraper

- Mix only one pouch at a time. The pot life is only 45 minutes.

- Optimal application temperature is 55-90°F

- Do not apply under direct sunlight, when it is raining or humidity is high

- Do not coat over control joints

Read the product label or the Technical Data Sheet of Rust-oleum RockSolid before application.

In spite of all care, if an application mishap does happen, recoating Rust-oleum RockSolid will let you get the finish you desire.

Recoating Rust-oleum RockSolid

Actually recoating Rust-oleum RockSolid is relatively easy. If you are already familiar with the application of Rust-oleum RockSoild, then the application of Rust-oleum Topcoat will be a breeze.

However you need to know the following important facts:

- Apply after 8-12 hours after applying Rust-oleum RockSolid Garage Floor Coating. Ensure the paint is no longer tacky.

- Must apply within 7 days of applying Rust-oleum RockSolid Garage Floor Coating.

- If applying after that, then sand the surface with 60-80 grit sandpaper before applying the topcoat, to ensure good adhesion.

This short video from Rust-oleum is very helpful.

FAQ

How soon can I apply the RockSolid Clear Topcoat?

Recoating Rust-oleum RockSolid with Rust-Oleum RockSolid Clear Topcoat can be done after 8-12 hours (ensure Garage Floor coating is not tacky) and within 7 days of applying RockSolid Garage or Metallic Floor coating.

Can I apply a 2nd coat of RockSolid? How soon can I apply a 2nd coat?

A second coat of RockSolid Floor can be applied. The floor can be recoated after 8-12 hours and before 7 days without sanding the surface for proper adhesion of the second coat.

Ensure the coating is not tacky prior to recoat.

If more than 7 days has passed, sand the surface with 60-80 grit sandpaper before applying the second coat.

Is RockSolid Slip Resistant?

Coated concrete produces a smoother surface and can become slippery when wet.

For an increased slip-resistant surface, recoating Rust-oleum RockSolid with RockSolid Clear Topcoat incorporating anti-slip additive will be helpful.

Thank you very much for reading the post. I do hope you found it informative and useful.