Is Polyurea The Same As Polyaspartic? (What You Need To Know!)

As an Amazon Associate, I earn from qualifying purchases.

Is Polyurea the Same as Polyaspartic?

Do you want a great looking garage floor that can take the wear and tear and still look as good as new. Chances are that you would already be aware of Epoxy Garage Floor Coatings. But have you also come across other coatings such as polyurethane, polyurea, polyaspartic, and polycuramine? And are you wondering “Is Polyurea the Same as Polyaspartic?”

Polyurea resin is a Polyurethane resin that can use either an aromatic isocyanate or an aliphatic isocyanate. Polyaspartic resin is essentially an aliphatic Polyurea resin. As such, Polyaspartic resin is a subset of Polyurea resin.

An important ingredient of any paint or coating is the resin, also known as the binder. The type of resin used, dictates several important properties of the coating, such as toughness, abrasion resistance and durability.

Epoxy is the most common resin used in coating applications, followed by polyurethane resin. Polyaspartic resin is a subset of Polyurea resin which in turn is a subset of Polyurethane resin.

What Is the Difference Between Epoxy Resin and Polyurethane Resin?

Organic resins are found in nature but industrial applications use inorganic resins. Inorganic resins are a polymer or a combination of polymers. Polymers are large molecules with repeating structural units of monomers.

“The simplest definition of a polymer is a useful chemical made of many repeating units”

Source: American Chemistry Council

The repeating unit is a combination of elements, usually carbon and hydrogen but often others like oxygen, silicon, chlorine etc.

The repeating unit in an epoxy is an epoxy ring (oxirane) made up of 1 oxygen & 2 carbon atoms.

“The polyurethane (PU) chemistry is a bit more complex. PU is formed by reactions between the two monomers, an isocyanate & a polyol. A broad spectrum of PU resins are possible as there is a wide range of isocyanates & polyols.”

Source: American Chemistry Council

This explains why you can have Polyaspartic resin as a subset of Polyurea resin and Polyurea resin as a subset of Polyurethane resin.

What Is Polyaspartic Polyurea?

You will often find manufacturers referring to their coatings as Polyaspartic Polyurea Coatings. As mentioned above, a Polyurethane polymer is formed by the reaction between two monomers, an Isocyanate and a Polyol.

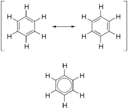

The Isocyanate in Polyurea can be either aromatic or aliphatic in nature. Aromatic compounds have cyclic or ring shaped geometry while aliphatic compounds have planar geometry.

Benzene: an example of Aromatic Structure

Propane: an example of Aliphatic Structure

Polyaspartic Polyurea is a Polyurea with an aliphatic Isocyanate.

What is the Difference Between Aliphatic and Aromatic Polyurea?

Simply stated, an aliphatic polyurea resin has a chain structure while an aromatic polyurea resin has a ring structure.

Aromatic Polyurea resin is the result of a reaction between an aromatic diisocyanate component and a synthetic resin blend component. The ring structure gives it superior stability.

Aromatic Polyurea is relatively fast curing and insensitive to moisture, making it a popular ingredient in several types of paints and coatings. However, it is not UV resistant and has poor color retention when exposed to sunlight.

Aliphatic Polyurea resin is the result of a reaction between an aliphatic diisocyanate component and a synthetic resin blend component.

Aliphatic Polyurea is more difficult to process and generally costs twice as much as an aromatic polyurea. However it has excellent UV resistance and is colorfast.

Is Polyaspartic Better Than Polyurea For Garage Floor Coating?

For a pure Polyurea Floor Coating System, using Aromatic Polyurea as the base coat and Aliphatic Polyurea will give you the best of both chemistries.

Aromatic Polyurea base coat will give you a matt finish with high level of chemical and moisture resistance at a lower cost, but with poor UV resistance. Aliphatic Polyurea topcoat will give you a high gloss, UV resistant, colorfast layer with improved durability. It does cost more though.

Should you want to use a Polyaspartic Coating on your garage floor I recommend using Rust-Oleum 277499 FastKote UV Stable Polyurea Floor Coating.

FastKote® UV is a high gloss, UV stable aliphatic polyurea floor coating for use in industrial and commercial facilities. Suitable for both interior and exterior applications.

FastKote UV complies with USDA FSIS regulatory sanitation performance standards for food establishment facilities. This coating is impervious to moisture and easily cleaned and sanitized.

In case you are looking for the best of the best in Garage Floor Coatings, then there is nothing better than using Rust-Oleum RockSolid Floor Coating Garage Kit.

RockSolid is a Polycuramine. Polycuramine Coatings combine the best of Polyurea, Urethane and Epoxy chemistries. This gives them a huge edge over Epoxy…and Polyurea for that matter. You can find out more about RockSolid by checking out my earlier post RockSolid Polycuramine Is Better Than Epoxy & Best Value for Money.

Thank you very much for reading the post. I do hope you found it informative and useful.