What Is Recessed Lighting in Garage Fire Code? (Fantastic Info!)

garagemadesimple.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com . The website is also an affiliate of a few other brands.

What Is Recessed Lighting in Garage Fire Code?

Are you planning to install recessed lighting in your garage? Fantastic! Recessed lighting adds class to a garage and makes it more livable. It is especially helpful when you need to maximize headspace in a garage with a low ceiling. On the flip side recessed lighting can be a fire hazard. So what is recessed lighting in garage fire code?

Recessed lighting cans can get extremely hot and increase the risk of fire. Section R302.6 of The 2021 International Residential Code (IRC) requires fire separation between dwelling and garage. If a garage has a dwelling unit above it, then the garage ceiling must be “not less than ½-inch gypsum board or equivalent”.

Recessed light cans can compromise the fire rating of the dwelling garage fire separation and result in a violation of the code, unless they are in a fire rated housing.

Garages located in cold climates often have blown-in or other types of insulation above the ceiling. There needs to be a separation between the hot recessed lighting can surface and the insulation to eliminate the risk of fire.

You are required to use IC rated cans that pass the UL 1590 test. Non-IC rated cans are permitted only if they are not in contact with the insulation. This regulation applies irrespective of whether there is a dwelling unit above the garage or not.

Click this link to find out more about recessed lights in a garage.

What Does IC and Non-IC Mean?

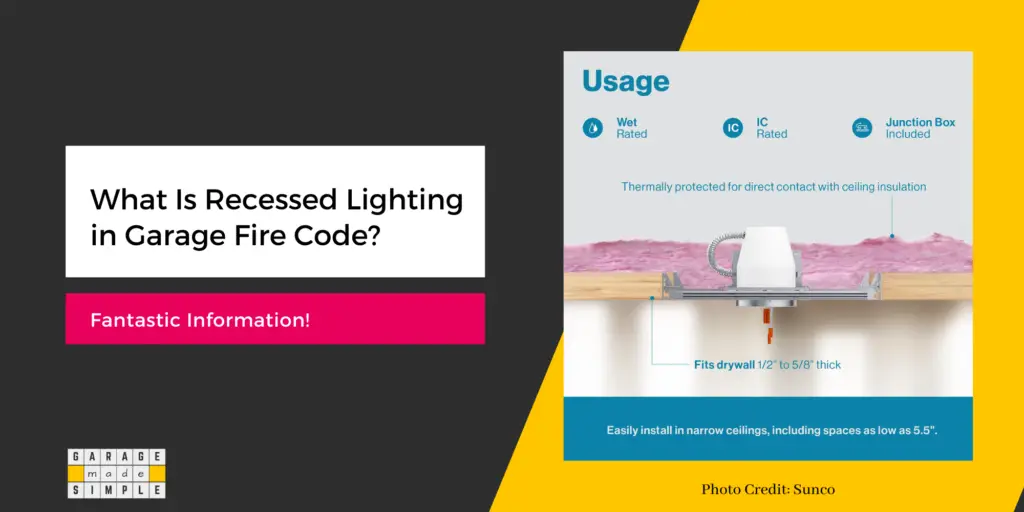

IC is an abbreviation for “insulation contact”. IC rated cans must be tested and certified under UL 1590.

IC rated recessed light cans complying to UL 1590 are constructed with a double wall design. In essence there are two cans, one within the other. The separation between the two cans ensures that the outer can remains cooler and therefore can be in direct contact with insulation.

Non- IC rated recessed light cans are single cans with holes to allow for ventilation and cooling. They are not designed to come in direct contact with insulation.

What is Code on Clearance from Thermal Insulation for Recessed Lighting?

Section 410.116 (B) Clearance from Thermal Insulation of the 2023 National Electric Code (NEC) states that thermal insulation shall not be installed above a recessed luminaires or within 75 mm (3”) of the recessed luminaire’s enclosure, wiring compartment, ballast, transformer, LED driver or power supply unless the luminaire is identified as type IC for insulation contact

Non-IC rated recessed light cans can, therefore, be installed in ceilings with insulation, only if they are placed within a housing that ensures a gap of at least 3 inches between the can and insulation.

What is Code for Energy Efficiency for Recessed Lighting?

Table N1102.4.1.1 (R402.4.1.1) AIR BARRIER, AIR SEALING AND INSULATION INSTALLATION of the 2021 International Residential Code (IRC) states as under:

Recessed light fixtures installed in the building thermal envelope shall be air sealed in accordance with section M1102.4.5

Further

Recessed light fixtures installed in the building thermal envelope shall be airtight and IC rated and shall be buried or surrounded with insulation.

Section N1102.4.5 (R402.4.5) Recessed Lighting is more specific.

Recessed luminaires installed in the building thermal envelope shall be sealed to limit air leakage between conditioned and unconditioned spaces. Recessed Luminaires shall be IC-rated and labeled as having an air leakage rate of not greater than 2.0 cfm (0.9 44 L/s) when tested in accordance with ASTM E283 at a pressure differential of 1.57 psf (75 Pa). Recessed luminaires shall be sealed with a gasket or caulked between the housing and the interior wall or ceiling covering.

Models that are airtight, IC rated and thermally protected, such as Sunco’s new construction cans, are designed to be installed in the ceiling surrounded by insulation. The cans won’t overheat and cause a fire. The airtight design keeps air conditioning or heating from leaking out of the garage through the housing.

Are IC Rated Recessed Light Cans Fire Rated?

IC rated recessed light cans are suitable for use in garages that have insulation above the ceiling. However, IC Rating is not the same as Fire Rating. If you have a bedroom or living room above the garage then you must use fire rated recessed lights.

Recessed lights require holes to be made in the drywall garage ceiling. In spite of best sealing or caulking of the gaps, the drywall ceiling’s fire resistance is compromised. Installation of recessed lighting in a garage with a dwelling unit above it will violate the IRC fire code.

The solution is to use fire rated recessed lights. Fire rated recessed lights use built-in intumescent pads to seal the gap. Intumescent pads expand quickly at high temperatures to slow the spread of flame & smoke.

DISCLAIMER: What Is the Safest Way to Handle Electrical Wires?

This post is for information only. I strongly recommend that all electrical work should be entrusted to licensed professional electricians. In case you do decide to do some of the work yourself, make sure that:

“Treat all electrical wiring, even “de-energized” ones as if it is live, unless it has been locked out and tagged”

You must follow the basic safety guidelines, as under:

- Use protective eyewear, especially when drilling or grinding metal

- Wear insulated rubber gloves when working on any circuit or branch circuit

- Always use insulated tools while working with electricity

- De-energize the electrical wires on which you will be working. Tag the circuit breaker to prevent someone from switching it on accidently

- Electrical wiring in wet or damp locations or underground must be within a PVC conduit

- Underground wiring conduits should be at least 18 inches below grade as per code

- All receptacles for equipment that could be in wet or damp locations should be equipped with Ground Fault Circuit Interrupter (GFCI)

- Never use old frayed cables, damaged insulation or broken plugs

- High voltage equipment should be properly grounded to insure electricity flows directly to the ground and not through the person in contact with the live wire

Thank you very much for reading the post. I do hope you found it informative and useful.